Products

Contact Us

Mobile: +86-159 8987 7778

Fax: +86-769 8713 1336

E-mail: tcj001@ccppbt.com

Address: Room 905, Fukang Commercial Building, Huangjiang, Dongguan City, Guangdong Province, China (Office: Yinzhou, Ningbo/Kunshan, Jiangsu Province)

Web: http://www.ccppbt.com

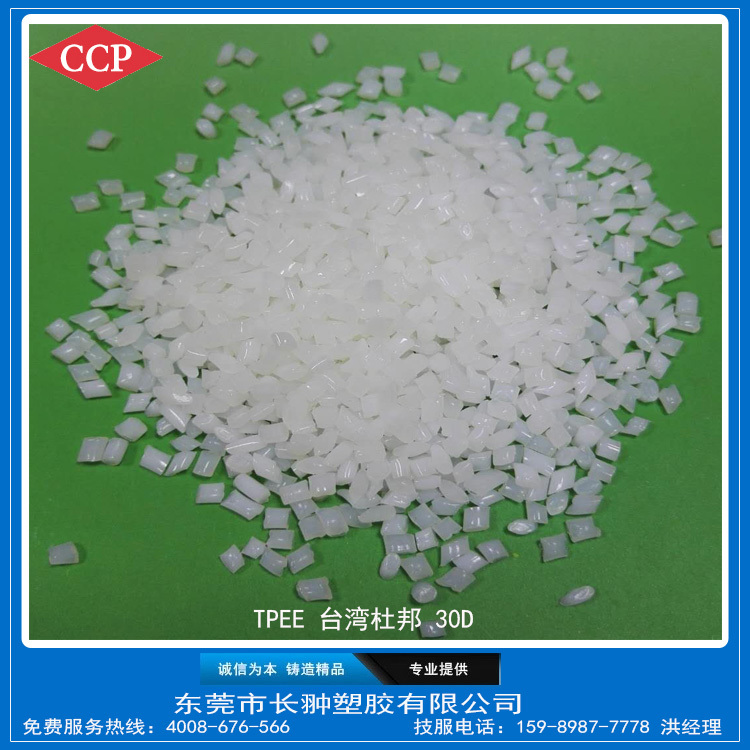

TPEE original factory sub-brand 30D

Classification:

- Product description

- Specific applications

-

Thermoplastic Polyester Elastomer TPEE

Complete specifications and hardness: 30D-72D. A large and stable supply of TPEE new materials and sub-brand materials, first-level agency in Changchun, direct sales from the manufacturer, professional service.

Application segmentation: Injection molding, extrusion, blow molding, modification.

1. Introduction:

CCP Thermoplastic Polyester Elastomer (TPEE) is an engineering plastic material developed by Changchun Company in response to industrial upgrades, after years of significant investment in human and material resources. It is produced using proprietary technology to supply the industry with the best quality TPEE at lower costs.

What is TPEE?

TPEE (Thermoplastic Polyester Elastomer) is a thermoplastic polyester elastomer made from 1,4-Butylene glycol and Polytetra-methylene glycol copolymerized with Dimethyl terephthalate (DMT) or Terephthalic acid (PTA), and can be made into thermoplastic polyester elastomer composite materials through mixing processes.

TPEE has many excellent properties and is widely used in the electrical, telecommunications, and automotive industries.

2. Characteristics of TPEE:

1. TPEE has the elasticity of rubber and the strength of engineering plastics; the soft segments give it elasticity, making it like rubber; the hard segments provide processing performance, making it like plastic. Compared to rubber, it has better processing performance and a longer service life; compared to engineering materials, it also has high strength, with better flexibility and dynamic mechanical properties.

2. Mechanical properties: By adjusting the ratio of soft to hard segments, the hardness of TPEE can range from Shore 30-82D, with its elasticity and strength lying between rubber and plastic. Compared to other thermoplastic elastomers, TPEE has a higher modulus under low strain conditions. When modulus is an important design condition, using TPEE can reduce the cross-sectional area of products and decrease material usage. TPEE has extremely high tensile strength. Compared to polyurethane (TPU), TPEE has a much higher compressive modulus and tensile modulus; using the same hardness TPEE and TPU to make the same part, the former can bear a greater load. Above room temperature, TPEE has a high bending modulus, and at low temperatures, it does not become overly rigid like TPU, making it suitable for making cantilever beams or torque-type components, especially suitable for high-temperature parts. TPEE has good low-temperature flexibility, with low-temperature notch impact strength superior to other TPEs, and wear resistance comparable to TPU. Under low strain conditions, TPEE exhibits excellent fatigue resistance and low hysteresis loss, which, combined with high elasticity, makes this material ideal for repeated cyclic load conditions, suitable for gears, rubber rollers, flexible couplings, and belts.

3. Thermal properties: TPEE has excellent heat resistance; the higher the hardness, the better the heat resistance. TPEE loses almost no weight when continuously heated at 110-140°C for 10 hours, and at 160°C and 180°C for 10 hours, the weight loss is only 0.05% and 0.1%, respectively, making the operating temperature of TPEE very high, with even higher short-term usage temperatures, able to withstand the baking and painting temperatures on automotive production lines (150-160°C), and it has minimal mechanical property loss at high and low temperatures. When used above 120°C, its tensile strength is far superior to TPU. Additionally, TPEE has outstanding low-temperature performance, with a brittle point below -70°C, and the lower the hardness, the better the cold resistance; most TPEE can be used long-term at -40°C. Due to the balanced performance of TPEE at high and low temperatures, its working temperature range is very wide, usable from -70 to 200°C.

4. Chemical medium resistance: TPEE has excellent oil resistance and can withstand most polar liquid chemical media (such as acids, bases, and amine glycol compounds) at room temperature, but it is ineffective against halogenated hydrocarbons (except for chlorofluorocarbons) and phenolic compounds. Its chemical resistance improves with increased hardness. TPEE has good anti-swelling and anti-permeation properties against most organic solvents, fuels, and gases, with fuel permeability only 1/3 to 1/300 that of oil-resistant rubbers like neoprene, chlorosulfonated polyethylene, and nitrile rubber. However, TPEE has poor resistance to hot water, and adding polyimide stabilizers can significantly improve its hydrolysis resistance.

5. Weather resistance and aging resistance: TPEE exhibits excellent chemical stability under various conditions, such as water mist, ozone, and outdoor atmospheric aging. Like most elastomers, it degrades under UV light, so for outdoor applications or products exposed to sunlight, UV protective additives should be added to the formulation, including carbon black and various pigments or other shielding materials; additionally, TPEE has varying degrees of hydrolysis.

For more details, please call: 159-8987-7778 or 133-7777-4387.

The product-related images are as follows, for reference only; please refer to the actual product.

TPEE sub-brand materials.

For more details, please call: 159-8987-7778 or 133-7777-4387.

-

TPEE Product Applications

TPEE is mainly used in fields that require shock absorption, impact resistance, flexibility, sealing, elasticity, oil resistance, chemical resistance, and sufficient strength. For example: polymer modification, automotive parts, high and low temperature resistant wire sheaths, hydraulic hoses, shoe materials, drive belts, rotationally molded tires, flexible couplings, soundproof gears, elevator guide rails, and corrosion-resistant, wear-resistant, high and low temperature resistant materials in chemical equipment pipeline valves, etc. Changchun TPEE can be divided into different grades based on applications, including extrusion grade TPEE, comb TPEE, drawing TPEE, rattan TPEE, soundproof gear TPEE, subway gasket TPEE, antenna pole sleeve TPEE, UV resistant TPEE, anti-UV TPEE, anti-static TPEE, and static dissipative TPEE products.For more details, please call: 159-8987-7778 or133-7777-4387

Previous Page

Next Page

Previous Page:

Next page:

Key words:

Product inquiry

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.

Related Products