Products

Contact Us

Mobile: +86-159 8987 7778

Fax: +86-769 8713 1336

E-mail: tcj001@ccppbt.com

Address: Room 905, Fukang Commercial Building, Huangjiang, Dongguan City, Guangdong Province, China (Office: Yinzhou, Ningbo/Kunshan, Jiangsu Province)

Web: http://www.ccppbt.com

PBT 4830F NCF

Classification:

- Product description

- Specific applications

-

The Dongguan Changchong professional team, utilizing 20 years of PBT sales service experience, provides a series of assistance from material identification, mold design, to molding processing. In addition, with support from the original factory in Changchun, we can also customize various special performance PBT composite engineering plastics for customers, thereby assisting them in enhancing product competitiveness.

Changchun Group in Taiwan (Since 1949)

ISO14001 and ISO/TS16949 certified factory

-----------------------------------

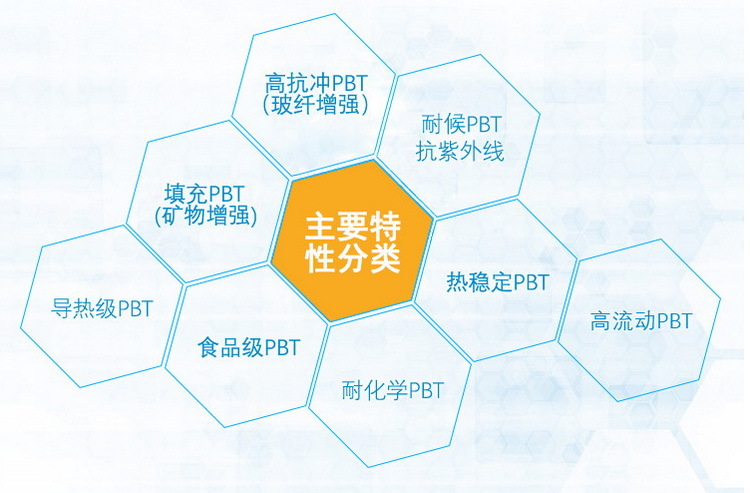

Over 200 standard specifications, mainly applied in:

1. Electronics, electrical appliances, mechanical components

2. Automotive parts (over 30 subdivided specifications, toughened and cold-resistant, Changchun PBT series/special alloy series)

3. High-end halogen-free flame retardant, meeting the requirements of high-end electronic products (over 10 application subdivisions)

4. Other extrusions, high RTI, high CTI, high insulation, low warpage and other special specifications

---------------------------------------------------------

Detailed certificate information:

★ Complies with EU RoHS directive and Sony-SS00259 environmental standards

★ Meets EU REACH regulation requirements

★ For detailed performance data and specific performance applicability, please call for consultation and sample testing (can provide at any time: detailed physical properties/SGS report/REACH report/UL/Sony GP certificate/MSDS/every batch COA, etc.)

----------------------------------------------------------------------------

For details, please call: 159-8987-7778 or 133-7777-4387

Sales service number

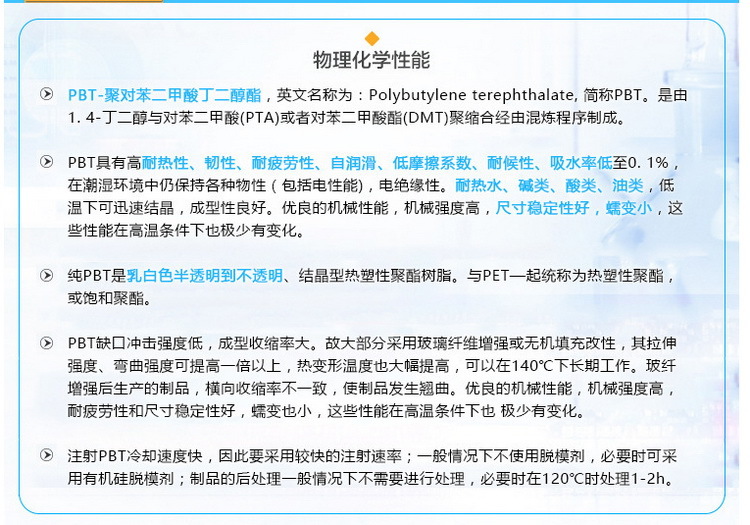

Characteristics of PBT:

1. PBT has excellent electrical insulation properties and low water absorption, thus maintaining performance even in humid environments.

2. PBT has good resistance to chemicals, solvents, and pharmaceuticals.

3. After glass fiber reinforcement, high heat-resistant PBT can withstand temperatures up to 210℃, with continuous use temperatures reaching 150℃.

4. PBT crystallizes quickly, has good fluidity, and excellent molding performance, allowing for the formation of thin-walled products with high molding efficiency.

5. PBT can also be blended and modified with various plastics to achieve complementary performance and meet usage requirements. This unreinforced PBT resin also has ultracharacteristics of ultrasonic welding.

6. In addition to the above five characteristics, PBT resin also has a low coefficient of friction, wear resistance, and low bending creep.

The product-related images are as follows, for reference only, please refer to the actual product.

For details, please call: 159-8987-7778 or 133-7777-4387

-

Specific applications of Changchun PBT:(1) Changchun Chemical's original factory specializes in composite modified PBT resin specifications, such as: automotive parts-specific PBT, automotive connector PBT, high toughness PBT, connector PBT, and other models of PBT. Designed specifically for automotive connectors, it meets requirements for high tensile strength, high strength, high toughness, low-temperature impact resistance, and repeated folding of thin walls.

(2) After modification by Changchun Chemical, various series of specifications and models of PBT have been developed for automotive parts and other industrial components, such as: automotive parts-specific PBT, automotive connector PBT, motor housing PBT, ignition coil PBT, connector PBT, high toughness PBT, low warpage PBT, high impact resistance PBT, low-temperature impact resistance PBT, low shrinkage PBT, low floating fiber PBT, high heat resistance PBT. In addition, various alloy materials have been developed, such as: PBT/PC alloy, PBT/ASA alloy, PBT/ABS alloy, PBT/AS alloy, PBT/SAN alloy. These are used in the production of automotive connectors, sensor components, click housings, wiper arms, headlight frames, lamp holders, and more.

(3) Based on the product requirements of the electronics and electrical industry, Changchun Chemical has developed various subdivided specifications, such as high RTI PBT, high CTI PBT, high glow wire PBT, high tracking resistance PBT, PBT that has passed F1 certification, PBT that has passed 5VA certification, halogen-free flame-retardant PBT, laser-engraved PBT, keycap PBT, low warpage PBT, and other subdivided specifications. These are used in the production of electronic and electrical connectors, coil skeletons, relays, temperature controller plastic housings, AV sockets, AC/DC plugs, computer keyboard keys, and other products.

For more details, please call: 159-8987-7778 or133-7777-4387

Previous Page

Next Page

Previous Page:

Next page:

Key words:

Product inquiry

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.

Related Products