Products

Contact Us

Mobile: +86-159 8987 7778

Fax: +86-769 8713 1336

E-mail: tcj001@ccppbt.com

Address: Room 905, Fukang Commercial Building, Huangjiang, Dongguan City, Guangdong Province, China (Office: Yinzhou, Ningbo/Kunshan, Jiangsu Province)

Web: http://www.ccppbt.com

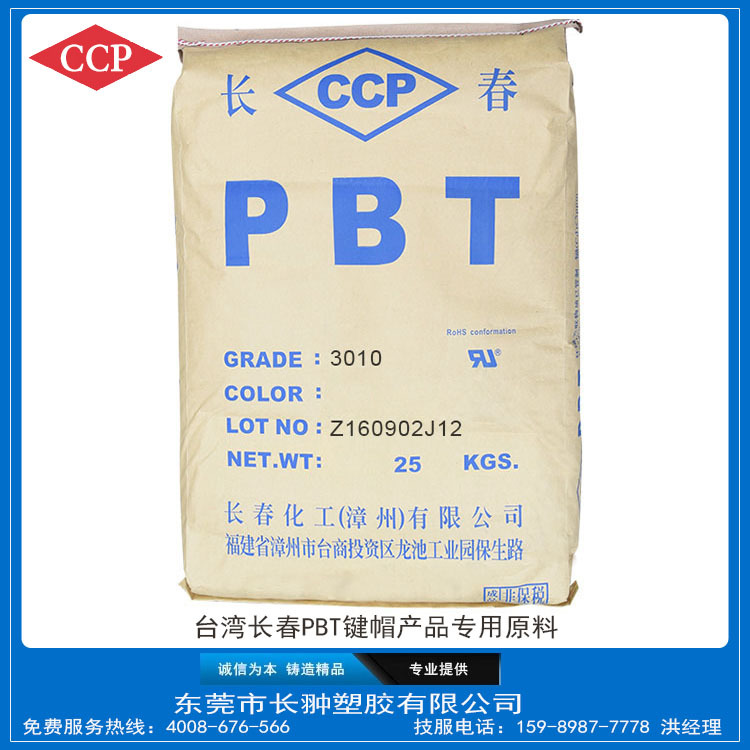

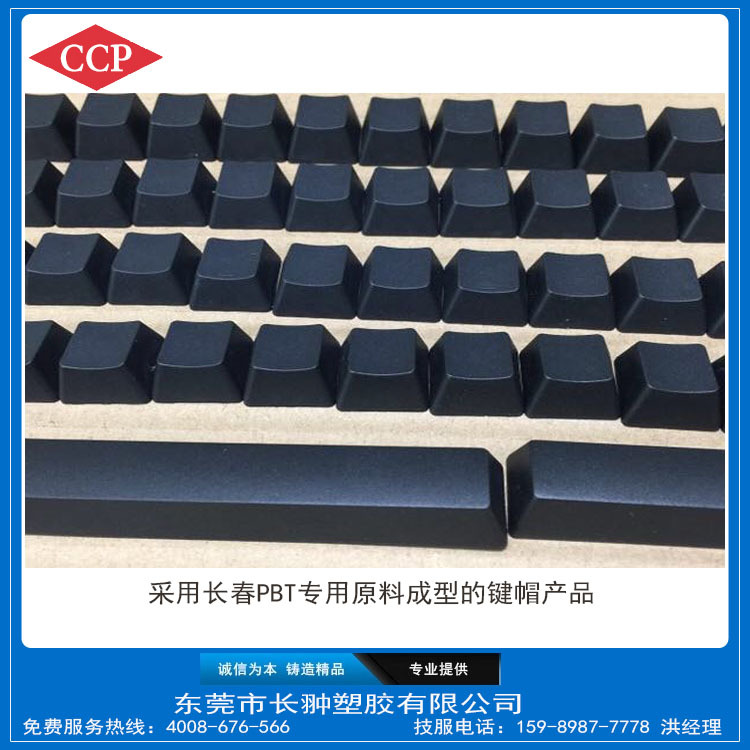

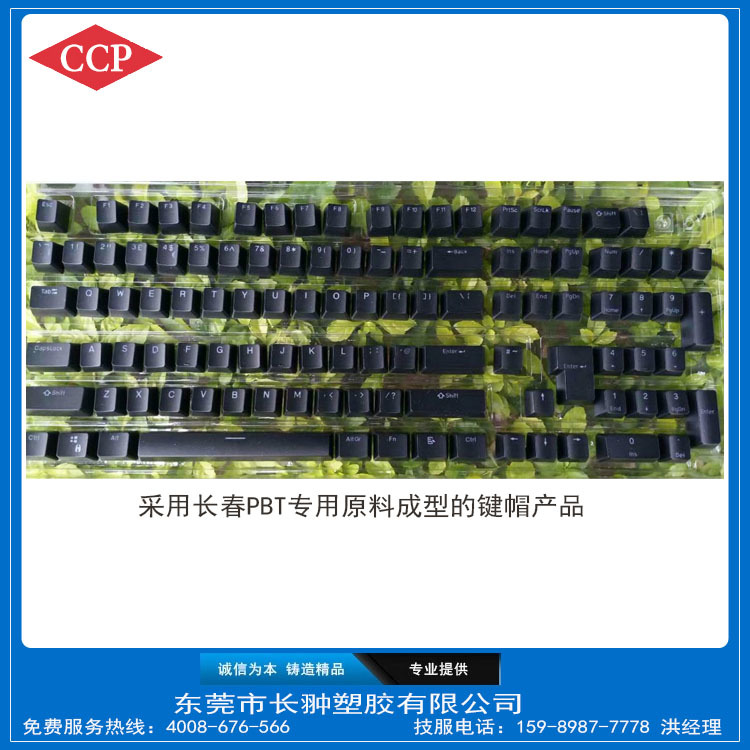

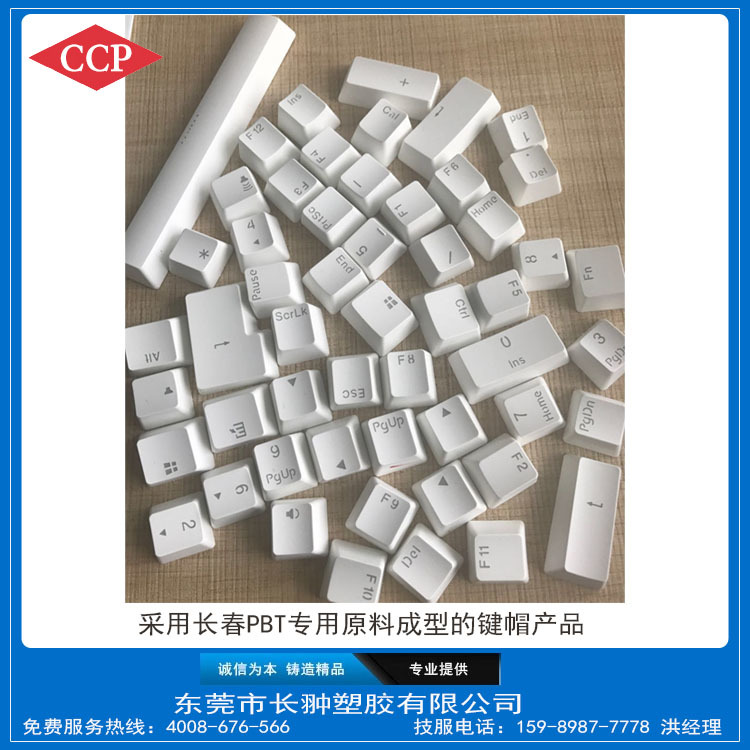

Keycap dedicated PBT material

Classification:

- Product description

- Specific applications

-

Dongguan Changchong Plastic has been deeply involved in the PBT keycap industry for many years, conducting extensive research in collaboration with Taiwanese R&D engineers.

A wealth of solutions has been summarized from the selection of basic materials, reducing gas emissions from materials, and the selection of auxiliary filling materials.

This maximizes the characteristics of PBT material and accelerates the replacement of ABS's oil leakage and slippery defects.

The main features and advantages are described as follows:

1. Solves the black and shiny problem of PBT keycaps in the industry, and minimizes the generation of light and shadow.

2. Solves the difficulty of one-time molding for the entire keycap, with excellent fluidity.

3. Solves the issues of white light-blocking and laser engraving effects for PBT.

4. Natural color specifications can be colored arbitrarily to meet personalized market demands.

5. Can meet the requirements of thermal sublimation and dyeing processes.

6. Assists in providing a series of experiences such as mold flow analysis, hot runner solutions, and mold development plans to optimize PBT keycap products.

Sales service number

Relevant product images are as follows:

For details, please call: 159-8987-7778 or 133-7777-4387

-

Specific applications of Changchun PBT:

(1) Specifications and models of professional composite modified PBT resin from Changchun Chemical, such as: automotive parts specific PBT, automotive connector PBT,high toughness PBT, connector PBT, and other models of PBT. Specifically for automotive connectors, it can meet the requirements of high tensile strength, high strength, high toughness, low temperature impact resistance,thin-walled repeated folding, and other requirements.(2) After modification by Changchun Chemical, various series of specifications and models of PBT have been developed for automotive parts and other industrial components.For example: automotive parts specific PBT, automotive connector PBT, motor housing PBT, ignition coil PBT, connector PBT, high toughness PBT, lowwarpage PBT, high impact resistance PBT, low temperature impact resistance PBT, low shrinkage PBT, low floating fiber PBT, high heat resistance PBT. In addition, various alloy materials have also been developed, such as: PBT/PC alloy, PBT/ASA alloy, PBT/ABS alloy, PBT/AS alloy, PBT/SAN alloy. These are used in the production ofautomotive connectors, sensor components, click housings, wiper arms, headlight frames, lamp bases, and so on.(3) According to the product requirements of the electronics and electrical industry, Changchun Chemical has developed various subdivided specifications, such as high RTI PBT,high CTI PBT, high glow wire PBT, high tracking resistance PBT, F1 certified PBT, 5VA certified PBT, halogen-free flame retardant PBT, laser engraving PBT, keycap PBT, low warpage PBT, and other subdivided specification products, which are used in the production of electronic and electrical connectors, coil skeletons, relays, thermostat plasticcomponent housings, AV sockets, AC/DC plugs, computer keyboard keys, and other products.For more details, please call: 159-8987-7778 or133-7777-4387133-7777-4387

Key words:

Product inquiry

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.

Related Products