Products

Contact Us

Mobile: +86-159 8987 7778

Fax: +86-769 8713 1336

E-mail: tcj001@ccppbt.com

Address: Room 905, Fukang Commercial Building, Huangjiang, Dongguan City, Guangdong Province, China (Office: Yinzhou, Ningbo/Kunshan, Jiangsu Province)

Web: http://www.ccppbt.com

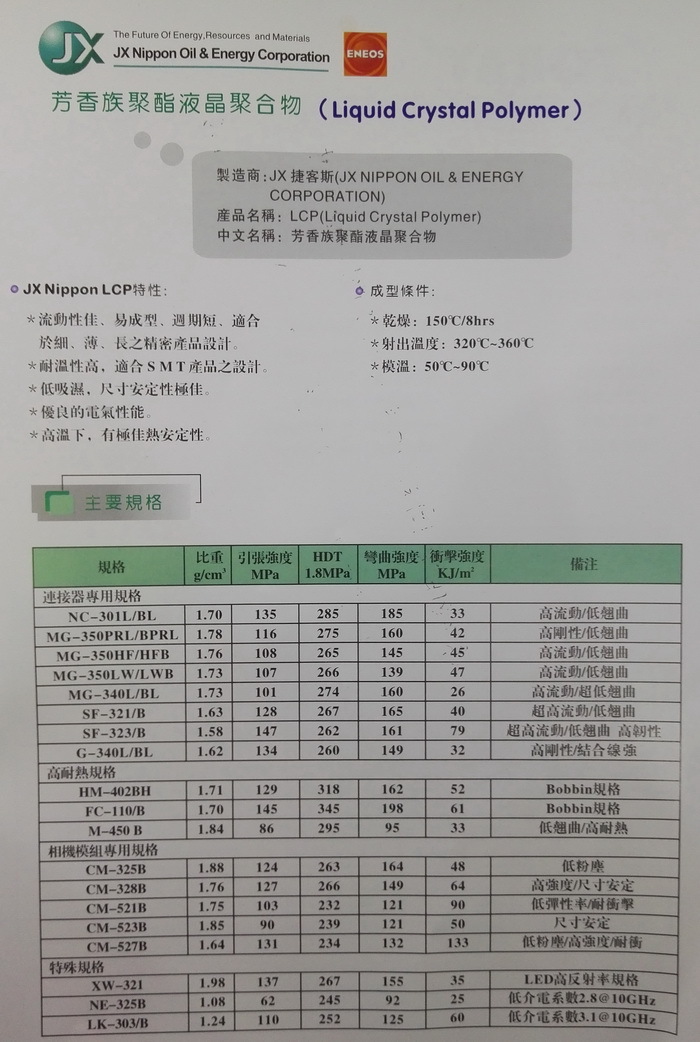

JX LCP CM-328B

Classification:

- Product description

- Specific applications

-

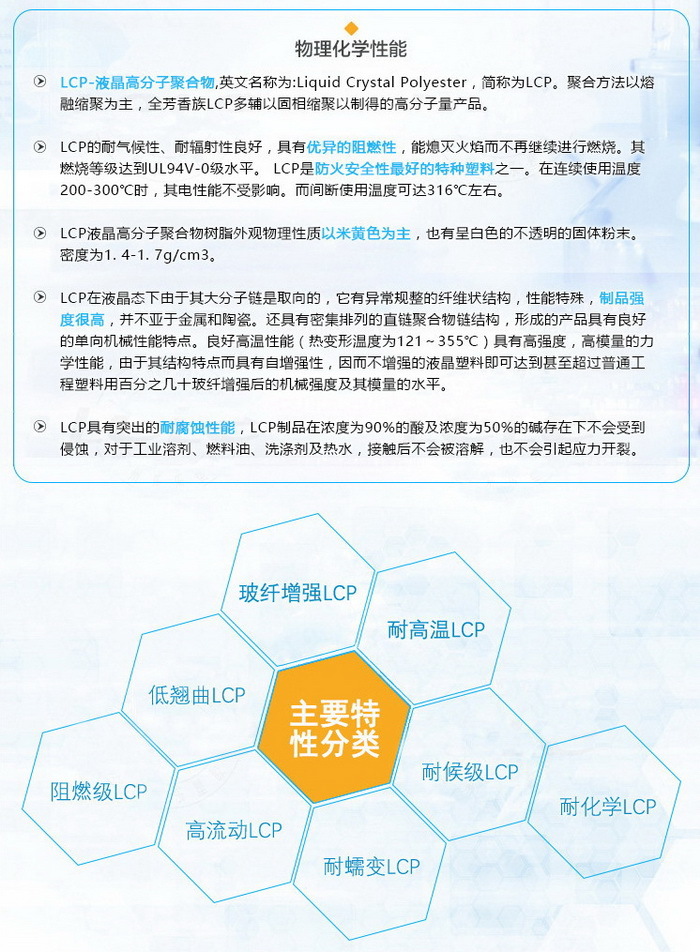

LCP Product Introduction:

1. LCP has good weather resistance and radiation resistance, with excellent flame retardancy, capable of extinguishing flames without continuing to burn. The natural flame retardant level of LCP plastic raw materials reaches UL94V-0 level, making it one of the best fire safety special plastics.

2. LCP has good fluidity and is easy to process and mold. Its molded products have a unique core-shell structure of liquid crystal polymers, and the resin itself has fiber properties, with high orientation in the molten state, which can provide a fiber reinforcement effect.3. LCP can be blended with various plastics to form polymer blends, in which liquid crystal polymers play a role in glass fiber reinforcement, significantly improving the strength, rigidity, and heat resistance of the materials.4. The density of LCP plastic raw materials is 1.4~1.7g/cm3. Liquid crystal polymers have high strength and high modulus mechanical properties, and due to their structural characteristics, they have self-reinforcement properties. Non-reinforced liquid crystal plastics can achieve or even exceed the mechanical strength and modulus levels of ordinary engineering plastics that have been reinforced with several tens of percent of glass fibers; if reinforced with glass fibers, carbon fibers, etc., they far exceed other engineering plastics.5. LCP liquid crystal polymers also have excellent thermal stability, heat resistance, and chemical resistance. The creep defects present in most plastics are negligible in liquid crystal materials, which also exhibit excellent wear resistance and friction reduction.6. LCP plastic raw materials have excellent electrical insulation properties, with dielectric strength higher than that of general engineering plastics and good arc resistance. They also have extremely good high-temperature characteristics, and as electrical application components, their electrical performance is unaffected at continuous use temperatures of 200~300℃. The intermittent use temperature can reach around 316℃.7. LCP plastic raw materials have outstanding corrosion resistance, and LCP products will not be eroded in the presence of 90% acid and 50% alkali. They will not dissolve upon contact with industrial solvents, fuel oils, detergents, and hot water, nor will they cause stress cracking.JX Nippon LCP Characteristics:

* Good fluidity, easy to mold, short cycle, suitable for the design of fine, thin, and long precision products.* High temperature resistance, suitable for SMT product design.* Low moisture absorption, excellent dimensional stability.* Excellent electrical performance.* Excellent thermal stability at high temperatures.For details, please call: 159-8987-7778 or 4008-676-566

Warm reminder: Product prices, specifications, and attributes are for reference only. For details, please call for consultation!

For details, please call: 159-8987-7778 or 4008-676-566

-

Application of LCP:

(1) LCP plastic materials have excellent high strength, high rigidity, high temperature resistance, and electrical insulation properties, and are used in fields such as electronics, electrical engineering, optical fibers, automotive, and aerospace.(2) LCP plastic materials have excellent electrical insulation performance, with dielectric strength higher than that of general engineering plastics, good arc resistance, and extremely good high-temperature resistance. LCP can be used to make printed circuit boards, electronic components for artificial satellites, and parts for jet engines. It can also be used in products such as electronic, electrical, and automotive mechanical parts or components.(3) LCP plastic materials can also be blended with plastics such as PBT and PA to form alloys, which have high mechanical strength after molding, replacing other engineering plastics reinforced with glass fibers, thus improving mechanical strength performance while enhancing usage strength and chemical stability.(4) LCP plastic materials can incorporate high fillers as packaging materials for integrated circuits, replacing epoxy resin as the packaging material for coil skeletons; LCP with high fillers can also replace ceramics as filling materials in chemical separation towers.

For more details, please call: 159-8987-7778 or 4008-676-566

Previous Page

Next Page

Previous Page:

Next page:

Key words:

Product inquiry

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.

Related Products