Products

Contact Us

Mobile: +86-159 8987 7778

Fax: +86-769 8713 1336

E-mail: tcj001@ccppbt.com

Address: Room 905, Fukang Commercial Building, Huangjiang, Dongguan City, Guangdong Province, China (Office: Yinzhou, Ningbo/Kunshan, Jiangsu Province)

Web: http://www.ccppbt.com

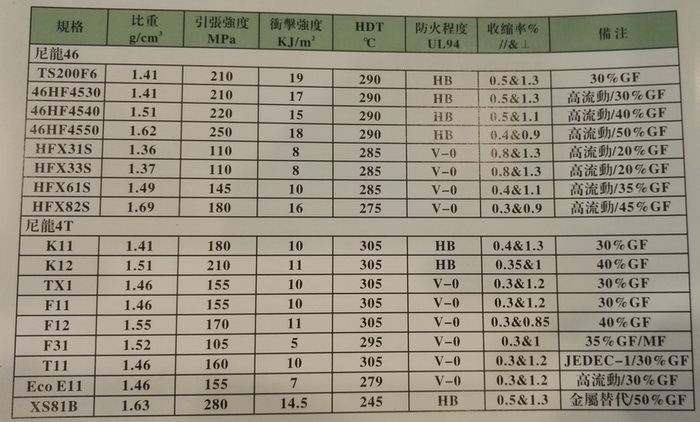

DSM PA46 46HF4540

Classification:

- Product description

- Specific applications

-

PA46 (Polyamide 46) is a new type of polyamide resin with a high melting point and high crystallinity. DSM (Royal DSM) was one of the first companies in the world to successfully establish a method for the industrial production of PA46, marketed under the name Stanyl, and has promoted it globally as a leading brand of heat-resistant and wear-resistant polyamide 46.

Molecular structure of PA46

PA46 is an aliphatic polyamide formed by the polycondensation of hexamethylenediamine and adipic acid. Although it has a molecular structure similar to nylon 66, Stanyl PA46 has more amide groups on each given length of the chain, and the chain structure is more symmetrical; this highly symmetrical chain structure results in a high crystallinity (about 70%) and a fast crystallization rate, leading to a higher melting point (295°C) and a high heat distortion temperature, with a long-term use temperature (CUT 5000 hours) reaching 163°C. These characteristics give Stanyl PA46 a technical advantage over other engineering plastics such as PA6, PA66, PPA, and polyester in terms of heat resistance, mechanical strength at high temperatures, wear resistance, etc., and it has a short molding cycle and is more economical to process.

Stanyl high-performance polyamide 46 has unparalleled performance and value in automotive and electronic applications, providing excellent mechanical properties, outstanding wear resistance, low friction, and excellent flowability under high-temperature conditions, making processing more convenient and special designs more flexible. The performance of Stanyl surpasses that of PPA, PA6T, and PA9T, and it typically outperforms PPS and LCP materials under high-temperature working conditions.

Processing performance

A: It has easy processability and excellent flow properties.B: It has excellent tensile strength and good thermal insulation properties.

C: Flame retardant, electroplatable, thermally stabilized, and heat-resistant.

D: High rigidity retention performance, while also exhibiting good high-temperature creep resistance.

E: Rigidity and creep modulus are comparable to PPS, PEI, and PES with the same level of glass reinforcement.

F: It can be used for thin-walled parts reaching 0.1 mm without flash.

G: PA46 plastic is a versatile, glass-reinforced, flame-retardant UL grade material that complies with UL VO regulations.

For details, please call: 159-8987-7778 or 4008-676-566

Kind reminder: Product prices, specifications, and attributes are for reference only. For details, please call for consultation!

For details, please call: 159-8987-7778 or 4008-676-566

-

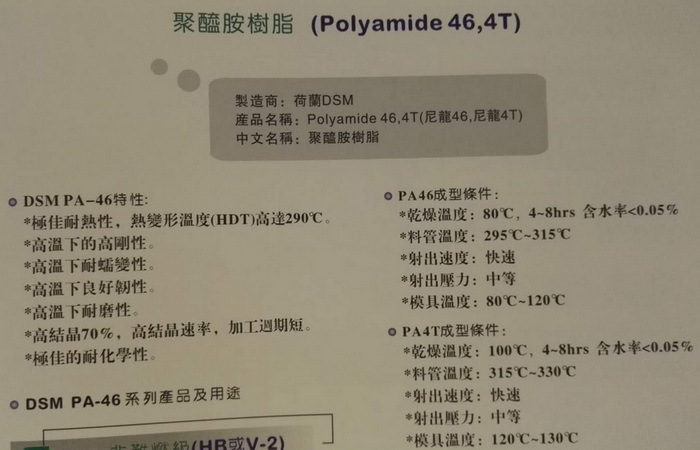

Introduction to DSM Stanyl (PA46) and PORTII (PA4T) products

It still has excellent mechanical and electrical properties at high temperatures of 290°C.

Its high crystallinity allows for a very short processing cycle and can be produced under a water cooling system, providing economic and safety advantages.

Successfully replaced expensive materials with high standards in the electronics field.

Successfully replaced some metal materials in the automotive industry.

DSM's newly developed low water absorption, high dimensional stability, high heat resistance (HDT 305), halogen-free flame retardancy, and excellent electrical properties for applications such as automotive and computer connectors, LED.

For more details, please call: 159-8987-7778or4008-676-566

Previous Page

Next Page

Previous Page:

Next page:

Key words:

Product inquiry

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.

Related Products