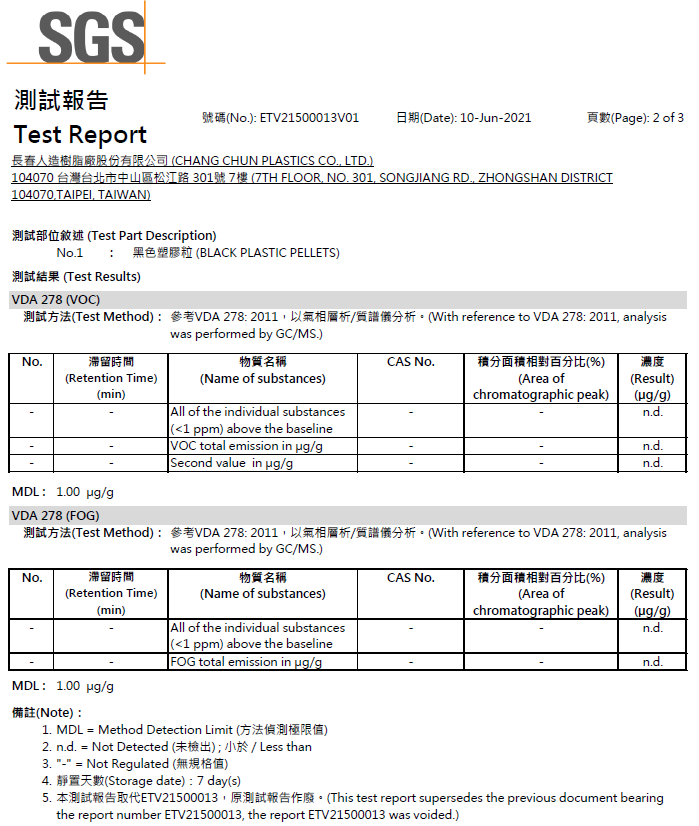

Changchun PBT 3030-104NX automotive seat special low odor PBT, low volatile PBT, low VOC PBT, low formaldehyde PBT, with complete testing and certification.

2024/03/23

PBT, polybutylene terephthalate, also known as poly(p-xylylene terephthalate), is a thermoplastic polyester that is milky white, semi-transparent to opaque, and crystalline in nature.

2018/04/09

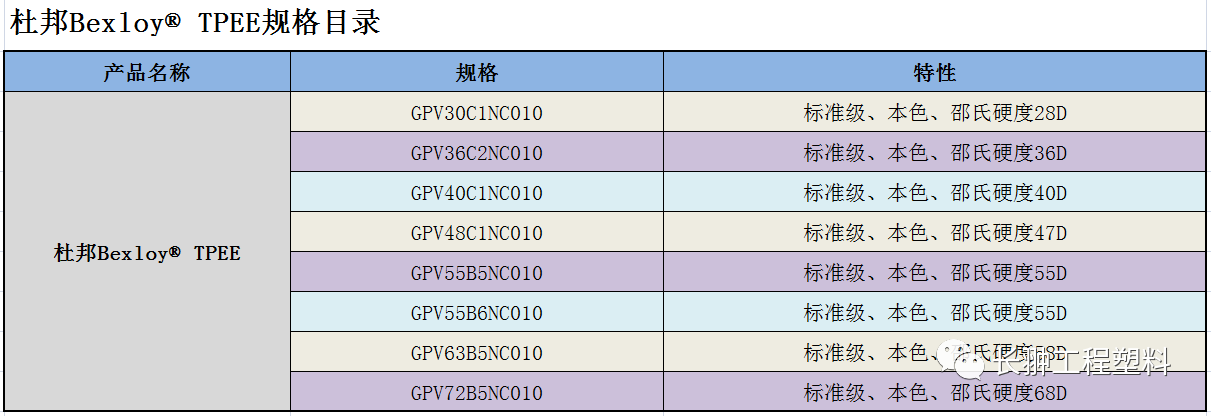

Analysis of TPEE polyester elastomer for toughening and modifying various plastics

TPEE is a block copolymer containing polyester hard segments and polyether soft segments; where the polyether soft segments and non-crystalline polyester form an amorphous phase, while the crystalline polyester hard segments form crystalline microregions, acting as physical crosslinking points. TPEE has the elasticity of rubber and the strength of engineering plastics; the soft segments give it elasticity, making it like rubber; the hard segments provide it with processing performance, making it like plastic; compared to rubber, it has better processing performance and a longer service life; compared to engineering materials, it also has high strength characteristics, while offering better flexibility and dynamic mechanical properties. TPEE possesses the elasticity of rubber and the strength of engineering plastics, as well as good flexibility, high melt stability, and low melt viscosity. It can be used to enhance the low and high-temperature impact strength (toughness), flexibility, and compatibility of blended systems of other plastics, and can also provide a certain degree of elasticity. Due to the presence of ester bonds, TPEE is a polar polymer, thus it can be used to modify polar materials such as POM, PBT, and PET. It can also be blended with PVC, or with PP, polyacetal, and CO-olefin alternating copolymers, or with other elastomers, to improve the impact toughness of these products.

2022/05/19

Hot plate welding is one of the earliest developed and simplest welding techniques in plastic welding technology. With the advancement of technology, the most commonly used welding methods now are vibration friction welding and ultrasonic welding. In addition, laser welding technology is also receiving increasing attention.

2018/03/12

CCP PBT LW Series - PBT for Laser Welding

The CCPPBTLW series is a brand new type of polybutylene terephthalate (PBT). Researchers at CCP have successfully improved its morphology, increasing the laser transmittance from 30% to nearly 60%—a first for PBT. The mechanical properties of the product are close to the standard model. Thanks to the improvement in laser transmittance, not only has the welding speed significantly increased, but the processing window has also been greatly expanded. The circumferential laser welding process is shown in Figure 1. Under the same laser power (50 W) and the same thickness of transparent welding parts (2 mm), the welding speed of standard PBT using a laser with a wavelength of 1064 nm is only 5-12 mm/s; whereas the welding speed of the CCPPBTLW series reaches 10-70 mm/s. Similar effects can also be achieved under other laser welding processes (such as quasi-synchronous welding) and processing parameters (such as higher laser power).

2018/03/19